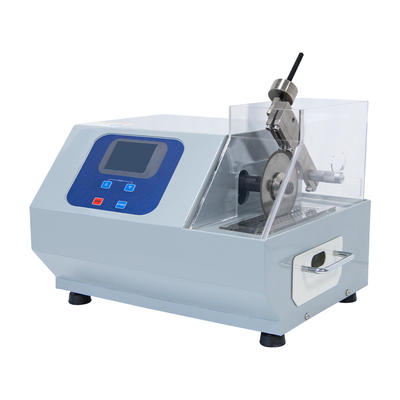

The main process of the work is that the heating ring in the fuselage tightly wraps the steel mold sleeve. The steel mold sleeve is a hollow cylindrical shape. Inside the hollow part, there is a lower mold connected to the screw rod. The screw rod moves up and down. Make the lower die in the steel die sleeve move with it. The upper half of the steel mold sleeve is the upper mold, and the upper mold can be moved out of the steel mold sleeve by the upward movement of the lower mold.

After taking out the upper mold, put the pattern to be inlaid on the lower mold, make the lower mold drop to the bottom position, add appropriate inlay powder, put the upper mold into the steel mold sleeve, and rotate the upper cover to the top of the upper mold , and then tighten the handle of the upper cover, and through the upward pressure of the lower mold and the high temperature of the steel mold sleeve given by the heater, the inlaid powder in the middle of the upper mold and the lower mold in the steel mold sleeve melts to form a solid plastic. At this time, the sample to be inlaid has been It is embedded into the bottom end of solid plastic, which is convenient for grinding and polishing the sample, and also conducive to the microstructure measurement under the metallographic microscope.

中文简体

中文简体 英语

英语 西班牙语

西班牙语 德语

德语

.jpg?imageView2/2/w/400/format/jpg/q/75)