1.Be sure to prepare the inlaid sample, open the iron block pressed on the top of the inlay machine, and place the metallographic sample you want to look down. Note that the place where the sample and the bottom of the inlay machine are in contact with each other is not allowed. There are sundries, otherwise, the uneven surface to be seen will be a headache after grinding.

2. Add an appropriate amount of bakelite powder or other thermosetting materials. It is not easy to say how much you add. You will know how many times you do it yourself.

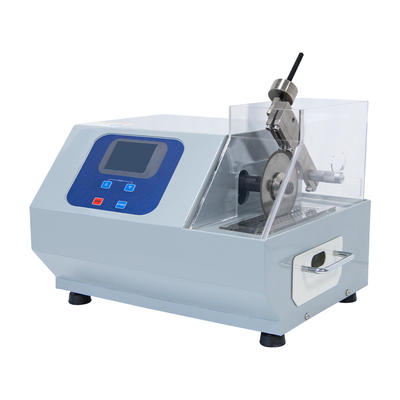

.png?imageView2/2/format/jp2)

3. Cover and press tightly, there should be a hand-cranking handle on the side and shake it until an indicator light is on.

4. Set the heating time and temperature according to the properties of the cured material. During this period, pay attention to the fact that the indicator light just now goes out and then continue to shake until it lights up.

5. Do not take out the sample immediately after the heating and heat preservation is completed, and finally wait until it is below 100 degrees before taking it out. Of course, your equipment has water cooling (automatic metallographic sample mounting machine), then it is better

中文简体

中文简体 英语

英语 西班牙语

西班牙语 德语

德语

.png?imageView2/2/w/400/format/jpg/q/75)

.jpg?imageView2/2/w/400/format/jpg/q/75)