Glass is an amorphous inorganic non-metallic materials, generally made of a variety of inorganic minerals (such as quartz sand, borax, boric acid, barite, barium carbonate, limestone, feldspar, soda ash, etc.) as the main raw material, in addition to a small amount of auxiliary raw materials. Its main components are silicon dioxide and other oxides. The chemical composition of ordinary glass is Na2SiO3, CaSiO3, SiO2 or Na2O·CaO·6SiO2, etc. The main component is silicate double salt, which is an amorphous solid with irregular structure. Glass is widely used in construction, daily use, art, medical treatment, chemistry, electronics, instrumentation, nuclear engineering and other fields.

Grinding and polishing scheme

Grinding and polishing

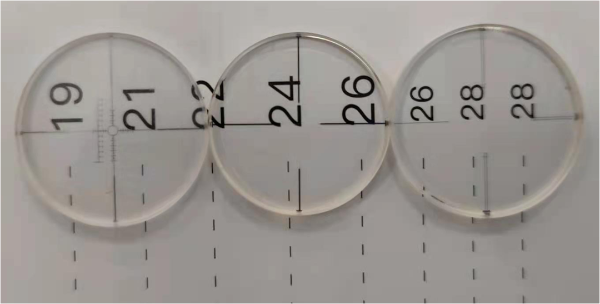

Using the OPT-380 Automatic Precision Grinder&Polisher with customized fixtures, glass of various shapes can be ground and polished. The glass can be pasted on the block with paraffin, or clamped by suction. Glass has high hardness and is fragile, so it should be ground with a finer diamond grinding disc as much as possible during the initial grinding, and the pressure should be moderate during grinding. When polishing, you should use the YR polishing cloth with medium fleece for polishing. The general polishing liquid cannot polish the glass brightly without scratches, but the cerium oxide polishing liquid can polish the surface of the glass very well.

Trojan recommends the following grinding and polishing process for reference:

|

Step |

1 |

2 |

|

Prepare the surface |

Diamond Grinding Disc |

YR polishing cloth |

|

Grain number |

P1500~P2000 |

2μmCerium Oxide Polishing Fluid |

|

Cooling lubricant |

Water |

/ |

|

Single specimen load /N |

20 |

proper pressure |

|

Time/ s |

120 |

20min |

|

Speed of lower disc/rpm |

60 |

80 |

Grinding with P1500 diamond grinding disc on the left, and polishing with cerium oxide in the middle

中文简体

中文简体 英语

英语 西班牙语

西班牙语 德语

德语