01 Cutting

Since it is necessary to observe the welding seam of the copper pipe, use the TableCUT-200 Automatic precision cut-off machine to cut it in half along its longitudinal axis.

TableCUT-200 Automatic precision cut-off machine

|

Equipment |

TableCUT-200 Automatic precision cut-off machine |

|

Consumables |

SiC cutting blade |

|

Parameter |

3000rpm,0.15mm/s |

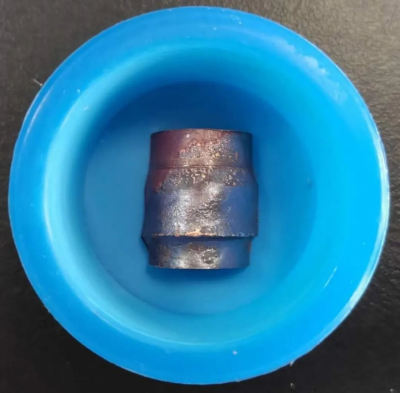

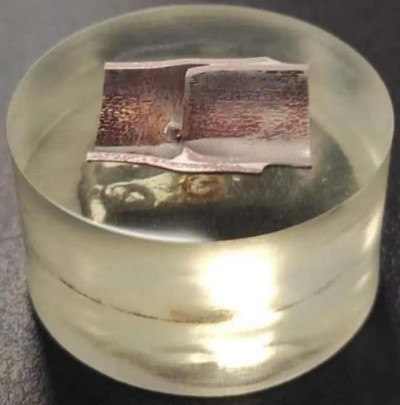

02 Mounting-cold mounting

Prepare TJ2210 acrylic resin powder and curing agent in proportion, and place the sample in a ThetaMount Pressure Cold Mounting Machine for pressure curing after pouring;

ThetaMount Pressure Cold Mounting Machine

Acrylic resin

|

Equipment |

ThetaMount Pressure Cold Mounting Machine |

|

Consumables |

TJ2210 |

|

Parameter |

0.2MPa,15min |

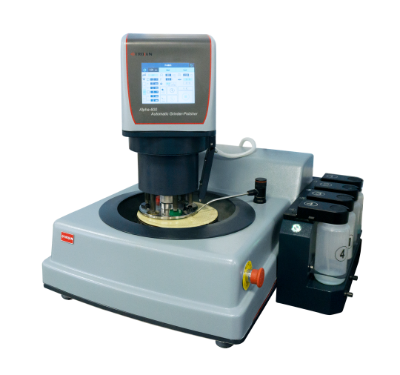

03 Grinding

Use Alpha-600 automatic grinding and polishing machine to grind the sample, sandpaper: P800→P2500;

Alpha-600 Automatic Grinder&Polisher

Metallographic abrasive paper

|

Equipment |

Alpha-600 Automatic Grinder&Polisher |

|

Consumables |

Abrasive paper:P800;P1200;P2000;P2500 |

|

Parameter |

Pressure: 15N,speed:130rpm,time:2min |

04 Polishing-rough polishing

Use Alpha-600 Automatic Grinder&Polisher to polish the sample, use YS polishing cloth with 3μm polycrystalline diamond suspension for rough polishing;

YS-JP White Fiber Polishing Cloth(PSA)

Polycrystalline diamond suspension

|

Equipment |

Alpha-600 Automatic Grinder&Polisher |

|

Consumables |

YS-JP White Fiber Polishing Cloth,3μm polycrystalline diamond suspension |

|

Parameter |

Pressure:20N,same direction speed:150rpm,time:3min |

05 Polishing-fine polishing

Use Alpha-600 Automatic Grinder&Polisher to polish the sample, use ZN polishing cloth with 0.05μm silica polishing liquid for fine polishing.

Black Polyurethane Polishing Cloth(PSA)

Silica Polishing Fluid

|

Equipment |

Alpha-600 Automatic Grinder&Polisher |

|

Consumables |

ZN-ZP Black Polyurethane Polishing Cloth,0.05μm Silica Polishing Fluid (Add 25 % ammonia and 3 % hydrogen peroxide) |

|

Parameter |

Pressure: 15N,same speed and direction:120rpm,time:1~2min |

06 Observation

|

Equipment |

MN 60 series microscope |

|

Consumables |

|

|

Parameter |

50×→500× |

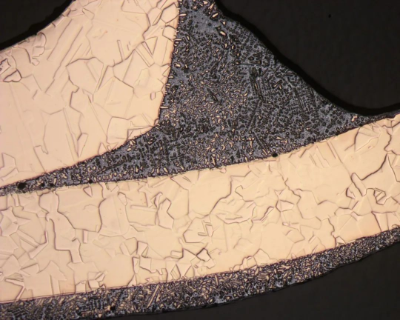

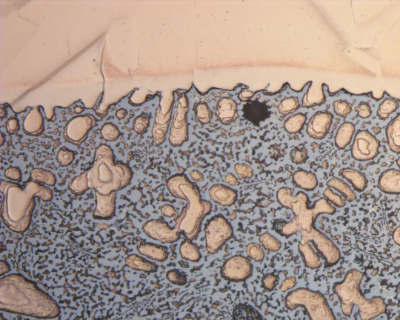

07 Analysis

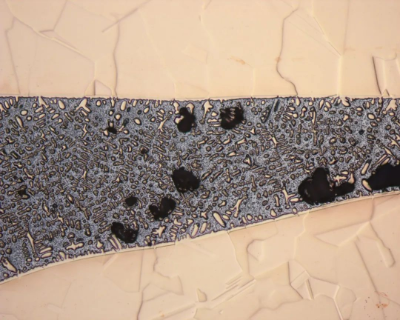

Copper phosphorus

weld 50×

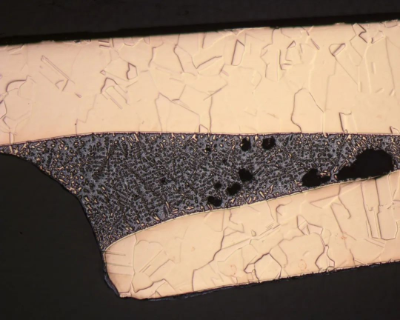

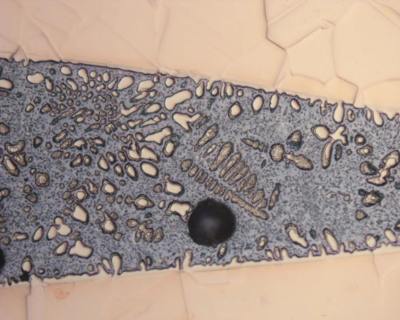

Copper phosphorus

weld 100×

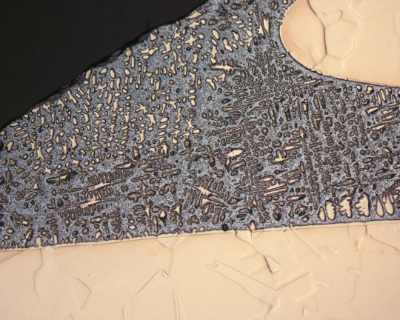

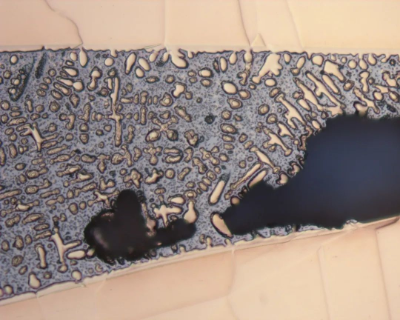

Copper phosphorus

weld 200×

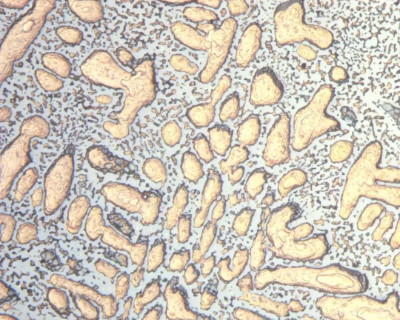

Copper phosphorus

weld 500×

Copper tubes have thin walls and low strength, so they are not suitable for hot mounting.

Copper is softer, use lower pressure when grinding.

It is difficult to remove copper scratches by simple mechanical polishing, so chemical mechanical polishing should be performed during fine polishing, and ammonia and hydrogen peroxide should be added to the silica polishing solution.

The base metal of the weld is pure copper, and it can be seen that it contains twin grains; the interdiffusion layer between the copper-phosphorus solder and the base metal is obvious; the weld structure is the primary Cu solid solution and the eutectic structure of Cu solid solution and Cu₃P.

中文简体

中文简体 英语

英语 西班牙语

西班牙语 德语

德语

.png?imageView2/2/w/400/format/jpg/q/75)