01 Equipment and Consumables

|

Equipment |

Trojan TableCUT-200 Automatic Precision Cut-Off Machine; Trojan FlexPRESS-600 automatic hot mounting press; Trojan ThetaMount Pressure Cold Mounting Machine; Trojan Theta Vacuum Cold Mounting Machine; Trojan Alpha-600 Automatic Grinder&Polisher; Trojan MN61 metallographic microscope; Electronic balance;hair dryer; |

|

Consumables |

Alcohol;Absorbent cotton;Disposable plastic cup;Disposable stirring rod; Trojan 0.05μm Non-Crystallizing Silica; |

02 Sample preparation process

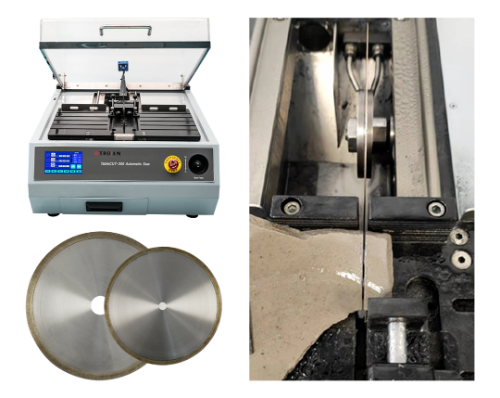

1-Cutting

Use TableCUT-200 automatic precision cutting machine with diamond cutting blades to cut ceramic pieces to proper shape and size.

|

Equipment |

TableCUT-200 Automatic Precision Cut-Off Machine |

|

Consumables |

Diamond cutting blade |

|

Parameter |

0.3mm/s,3000rpm |

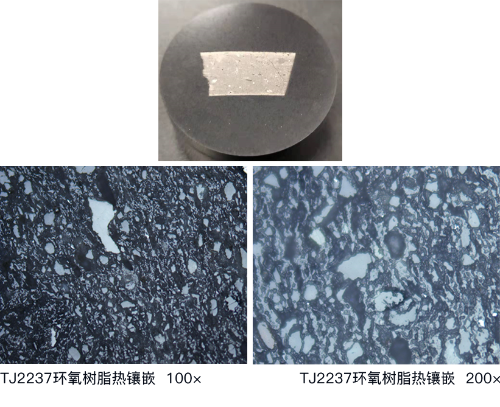

2.1-Mounting(hot mounting TJ 2237)

Use FlexPRESS-600 automatic hot mounting machine with TJ2237 epoxy resin to mount the sample.

|

Equipment |

FlexPRESS-600 hot mounting press |

|

Consumables |

TJ 2237 |

|

Parameter |

170℃,5min,100bar |

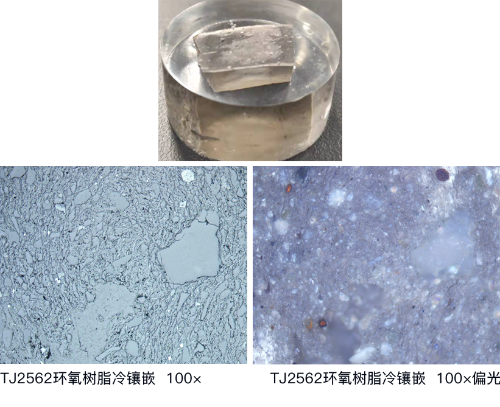

2.2-Mounting(cold mounting TJ 2562)

It was found that there are a lot of pores in the pottery shards. Use TJ2562 for vacuum mounting. The resin was mixed in proportion to vacuum mounting in a Theta Vacuum Cold Mounting Machine, and the sample was placed in a ThetaMount Pressure Cold Mounting Machine for pressure curing for about 12

|

Equipment |

Theta Vacuum Cold Mounting Machine、ThetaMount Pressure Cold Mounting Machine |

|

Consumables |

TJ 2562 |

|

Parameter |

0.2MPa,12h |

3-Grinding

Use Alpha-600 automatic grinding and polishing machine to grind the sample, sandpaper: P400→P2500.

|

Equipment |

Alpha-600 Automatic Grinder&Polisher |

|

Consumables |

Abrasive paper:P400;P800;P1200;P2000;P2500 |

|

Parameter |

Pressure:20N,speed:200rpm,time:2min |

4.1-polishing (rough polishing)

Use Alpha-600 automatic grinding and polishing machine to polish the sample, first use CS polishing cloth, alternately use 3 μm polycrystalline diamond polishing fluid and 0.05 μm silicon dioxide polishing fluid for rough polishing.

|

Equipment |

Alpha-600 automatic grinder&polisher |

|

Consumables |

CS polishing cloth,3μm Polycrystalline Diamond Suspension&0.05μm Non-Crystallizing Silica |

|

Parameter |

Pressure:25N,speed of same direction: 150rpm,time:300s |

4.2-Polishing (fine polishing)

Use an Alpha-600 automatic polishing machine to polish the sample, and then use an ET polishing cloth with a 0.05 μm silica polishing solution for fine polishing.

|

Equipment |

Alpha-600 automatic grinder&polisher |

|

Consumables |

ET polishing cloth,0.05μm Non-Crystallizing Silica |

|

Parameter |

Pressure: 20N,speed of same direction: 120rpm,time: 60s |

5-observation

|

Equipment |

MN 60 series microscope |

|

Consumables |

|

|

Parameter |

50×→500× |

03 Analysis

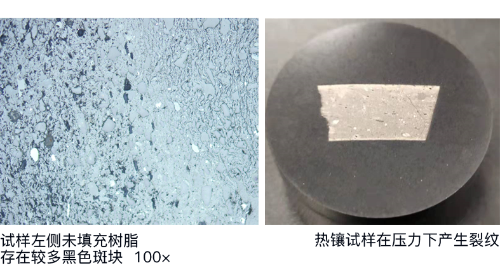

The quality of the customer's thermal mounting sample is poor, and there are gaps between the resin and the sample. In order to prevent cross-contamination between different abrasive particles, it is recommended to perform ultrasonic cleaning between each pass. Secondly, the thermal mounting material has not been completely burned through and fused, and blocks and discoloration have occurred after grinding and polishing. It is recommended to improve. The petrographic facies of the sample can be prepared by both cold mounting and hot mounting. The hot mounting is cracked due to the pressure during the mounting process; the cold mounting is vacuumed to fill the pores inside the pottery.

The main purpose of preparing samples is to test the chemical composition of pottery sherds. Hot mounting may cause some loose substances to fall off due to the lack of resin support in the internal pores of the sample, while vacuum cold mounting will fill the interior of the pottery with resin, resulting in interference elements when the energy spectrum is applied, but these interference elements are easy to exclude.

中文简体

中文简体 英语

英语 西班牙语

西班牙语 德语

德语

.jpg?imageView2/2/w/400/format/jpg/q/75)

.png?imageView2/2/w/400/format/jpg/q/75)