1. Mechanical mosaic method

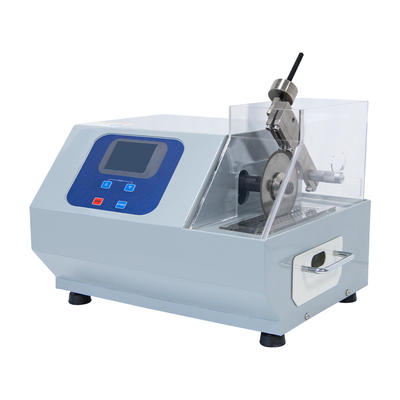

The mechanical inlay method (metallographic inlay machine, metallographic sample inlay machine) is to first place the sample in the holder or sample holder, and then fix it with screws and spacers. The modified method is simple to operate, and is suitable for samples with regular shapes and small sizes.

2. Resin inlay method (metallographic inlay)

The resin inlay method is to use metallographic inlays to inlay small metallographic samples, and samples of any shape can be inlaid into samples of a certain size. The resin inlay method can be divided into two categories: hot pressing inlay method and pouring inlay method.

1) The hot-pressing inlay method is to heat polyvinyl chloride, polystyrene or bakelite powder to a certain temperature, apply pressure and hold for a certain period of time, use the inlay material to firmly bond with the sample, and then grind the sample. . Hot press mounting needs to be done with a metallographic mounting machine (metallographic specimen mounting machine).

2) Casting inlay method: Since the hot pressing inlay method requires heating and pressure, it has a certain influence on quenched steel and soft metals, so the cold pouring method can be used. The casting mounting method is suitable for samples that do not allow heating, soft or low melting point samples, samples with complex shapes and porosity, etc., or used without mounting equipment. Practice has proved that it is better to use epoxy resin, stir evenly according to the ratio in the instructions, inject it into the prepared mold, and it can be solidified and demolded after a period of time.

中文简体

中文简体 英语

英语 西班牙语

西班牙语 德语

德语

.jpg?imageView2/2/w/400/format/jpg/q/75)