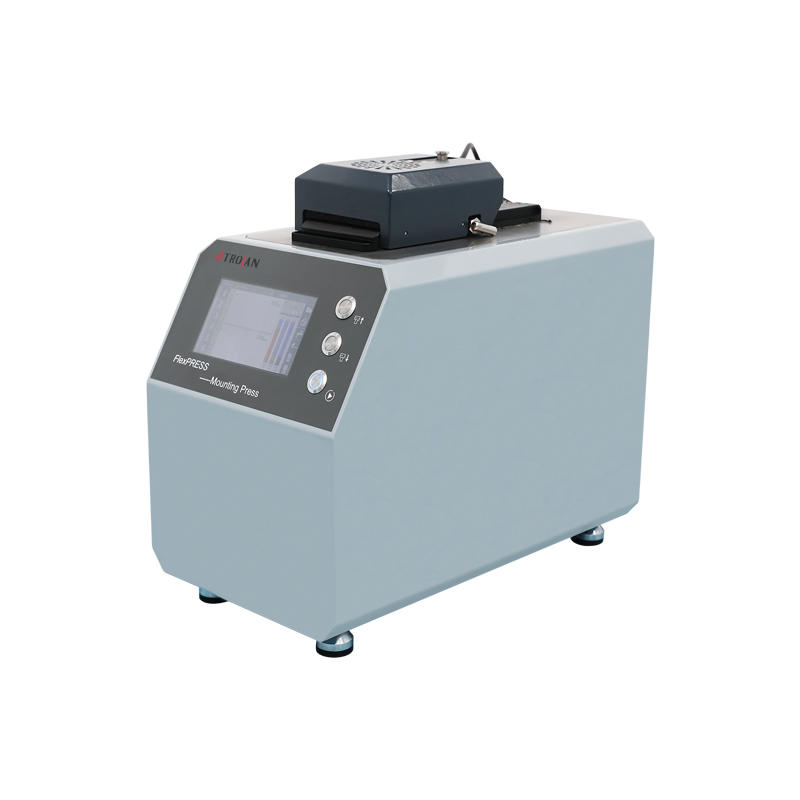

Mounting press machines are an essential tool in the manufacturing industry, primarily used for creating high-quality samples for microscopic examination. They are also used in research and development, material testing, and quality control. The mounting press machine is designed to prepare metallographic samples for observation under a microscope. The machine applies heat and pressure to the sample to embed it in a plastic resin material, which makes it easier to cut, grind, and polish.

In this article, we will discuss the working of a mounting press machine, the different components involved, and the steps involved in the sample preparation process.

A typical mounting press machine consists of several components, including a heating unit, a cooling unit, a pressure unit, and a mold assembly. The heating unit is responsible for heating the resin to its melting point, while the cooling unit helps to cool it down to a temperature that allows it to solidify around the sample. The pressure unit provides the necessary force to press the sample and the resin together, ensuring that the sample is evenly embedded within the resin.

Working of a Mounting Press Machine

The working of a mounting press machine involves several steps, as outlined below:

Step 1: Sample Preparation

The first step in the process is to prepare the sample for embedding. The sample must be cleaned, dried, and polished before being placed in the mold assembly.

Step 2: Resin Preparation

The next step is to prepare the resin for embedding. The resin is heated to its melting point, usually between 100°C and 200°C, in the heating unit. Once the resin has melted, it is poured into the mold assembly.

Step 3: Sample Embedding

The sample is carefully placed in the mold assembly, and the pressure unit is activated. The pressure unit applies force to the sample and resin, ensuring that the sample is evenly embedded within the resin.

Step 4: Cooling

Once the sample is embedded in the resin, the cooling unit is activated, which cools down the resin and solidifies it around the sample. The cooling process typically takes between 5 and 15 minutes, depending on the resin used.

Step 5: Sample Removal

After the resin has solidified, the mold assembly is opened, and the sample is removed. The sample is now ready for cutting, grinding, and polishing.

A mounting press machine is a vital tool in the manufacturing industry, used for creating high-quality samples for microscopic examination. The machine applies heat and pressure to embed the sample in a plastic resin material, making it easier to cut, grind, and polish. Understanding the working of a mounting press machine and the different components involved is crucial in ensuring the quality of the samples produced.