The ThetaVAC-2 Vacuum Cold Mounting Machine is a vacuum impregnation cold mounting device specifically designed for the cold mounting of epoxy resin. Its principle is to enable the rapid penetration of epoxy resin into tiny pores and cracks through a vacuum environment, achieving bubble-free filling. It is especially suitable for the edge protection and maintenance of structural integrity of porous and fragile materials. It is suitable for porous materials (such as crack failure analysis, porous castings, and composite materials), electronic components, rocks and minerals, ceramics, and sprayed coatings, and has the following features:

- It adopts a program-controlled system, allowing users to customize parameters such as vacuum degree, the number of cycles, and time. It is equipped with a 5-inch touch screen for convenient operation.

- The extra-large vacuum chamber (inner diameter Φ252mm) can process 12 samples with a diameter of 40mm simultaneously.

- The electric rotating table makes pouring convenient and quick.

- The Teflon-coated inner wall is easy to clean.

- The low-noise design (55-60dB) optimizes the laboratory environment.

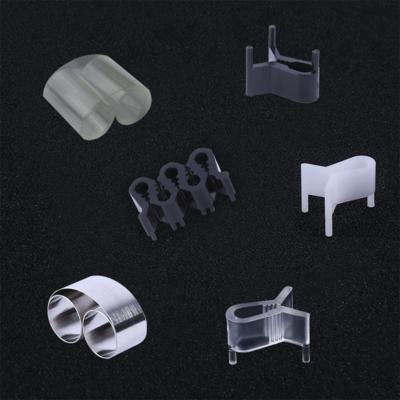

The following are the porous samples on the PCB board after vacuum impregnation using the ThetaVAC-2 Vacuum Cold Mounting Machine.

中文简体

中文简体 英语

英语 西班牙语

西班牙语 德语

德语