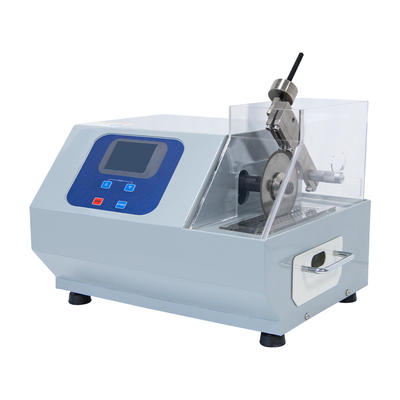

The advanced control system of the intelligent fully automatic Brinell hardness tester is the key to its efficient and accurate testing. The system is mainly composed of three parts: hardware control module, software algorithm module and human-computer interaction interface. The hardware control module is responsible for performing specific physical operations, such as the lifting and lowering of the indenter, the control of the applied pressure, etc.; the software algorithm module integrates advanced control algorithms and logical judgments, and is responsible for guiding the operation sequence and precision control of the hardware module; the human-computer interaction interface provides users with an intuitive operation interface and result display, making the test process more convenient and friendly.

In the control system of the intelligent fully automatic Brinell hardness tester, the integrated application of algorithms and logical control is the core of realizing the automation of the test process. These algorithms and logical controls cover the entire process from the pressure applied by the indenter, the indentation measurement to the hardness value calculation, ensuring the accuracy and consistency of the test.

Control of the pressure applied by the indenter: By integrating advanced pressure control algorithms, the control system can accurately control the lifting and lowering speed of the indenter and the size of the applied pressure. During the test, the system will automatically adjust the applied pressure of the indenter according to the preset test parameters to ensure the accuracy of the test results. At the same time, the system can also monitor pressure changes in real time to avoid test errors caused by pressure fluctuations.

Automation of indentation measurement: After the indentation is formed, the control system automatically starts the indentation measurement module. This module uses a high-precision sensor to collect the size data of the indentation, and accurately identifies and measures the indentation through an integrated image processing algorithm. This process does not require human intervention, which greatly improves the test efficiency and accuracy.

Intelligent calculation of hardness value: Based on the collected indentation data, the control system will use the Brinell hardness calculation formula to automatically calculate the hardness value of the material. This calculation process is not only fast and accurate, but also can be adaptively adjusted according to the type of material and test conditions to ensure the reliability of the test results.

Thanks to the integrated application of advanced control systems, the intelligent fully automatic Brinell hardness tester can fully automate the test process. From sample placement, pressure applied by the indenter, indentation measurement to hardness value calculation, the entire process does not require human intervention, which greatly saves test time and labor costs. The automated test process also improves the continuity and consistency of the test, making the test results more reliable.

In addition to automating the test process, the control system of the intelligent fully automatic Brinell hardness tester also has intelligent monitoring and fault warning functions. By real-time monitoring of the equipment's operating status and test data, the system can detect potential faults or anomalies in a timely manner and automatically trigger an early warning mechanism. This helps users take timely measures to avoid the impact of faults on the test process and ensure the smooth progress of the test.

Intelligent fully automatic Brinell hardness tester has been widely used in the fields of materials science and industrial manufacturing with its advanced control system and high-precision sensors. From aerospace, automobile manufacturing to new energy, electronic information and other industries, the equipment has demonstrated excellent test performance and reliability. In the future, with the continuous development of the Internet of Things, big data and artificial intelligence technologies, the intelligent fully automatic Brinell hardness tester is expected to achieve more intelligent testing and management, providing users with a more convenient and efficient testing experience.

中文简体

中文简体 英语

英语 西班牙语

西班牙语 德语

德语

.jpg?imageView2/2/w/400/format/jpg/q/75)