In ancient times, iron axes were used in agricultural production to cut down trees, reclaim wasteland, and repair farmland. In military terms, iron axes, as a weapon, also had certain equipment requirements.

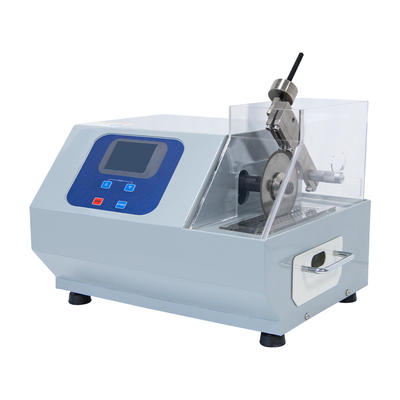

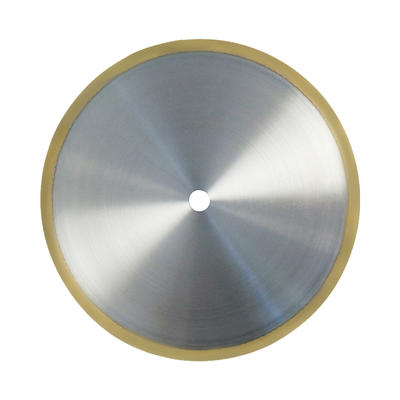

During the Tang Dynasty, iron smelting technology developed and improved on the basis of the previous generation. More advanced blasting equipment was used to increase the furnace temperature, which improved the output and quality of iron, providing material and technical conditions for the mass production of iron axes. Existing ancient iron axe samples were prepared for metallographic sampling. Because the samples cannot be damaged and are large in size, a large-diameter grinding disc Alpha210 double-disc dual-control grinding and polishing machine was used for manual grinding and polishing.

Sample preparation plan: SiC sandpaper P400, P800, P1200 → SC polishing cloth + 3μm polycrystalline diamond polishing liquid for polishing → 4% nitric acid alcohol solution etching, and an 80MN metallographic microscope was used to observe the structure, see the attached figure.

From the metallographic photos, it can be seen that the back of the axe is a block ferrite, and the black ones are the pits left by the inclusions. The blade is composed of reticular ferrite and bainite, as well as Widmanstätten structure produced after overheating. In order to improve the strength and toughness of the blade, the craftsmen hammered and forged it after heating. Due to the immature technical conditions at the time, the obtained structure was not ideal, but it greatly promoted the later smelting and manufacturing process.

中文简体

中文简体 英语

英语 西班牙语

西班牙语 德语

德语

.png?imageView2/2/w/400/format/jpg/q/75)