In material testing, the sample preparation process is regarded as the core link of the entire testing process. The quality of the sample directly affects the accuracy and reliability of the test results. A poorly prepared sample may cause distortion of test data due to internal defects, surface unevenness or chemical property changes, thus affecting the accurate evaluation of material performance. Therefore, how to prepare high-quality, flawless samples has become the focus of common concern for material scientists and engineers.

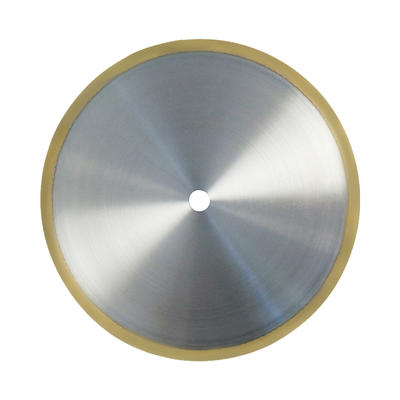

As an efficient and reliable sample preparation equipment, the pressure cold mounting machine has become an ideal choice for solving the sample preparation problem with its precise pressure and temperature control and advanced mounting technology. The device can achieve precise control of pressure and temperature during the mounting process through precise mechanical structure and intelligent control system, thereby ensuring that the sample does not change its physical and chemical properties during the mounting process.

In the mounting process, pressure control is crucial. The pressure cold mounting machine can monitor and adjust the pressure value during the mounting process in real time through the built-in pressure sensor and precise hydraulic system. This precise pressure control not only helps the uniform distribution of resin materials, but also effectively avoids the generation of bubbles and pores inside the sample. At the same time, appropriate pressure can also promote the close bonding between the resin and the sample, and improve the overall strength and stability of the sample.

Temperature is a key factor affecting the quality of resin curing and sample preparation. The pressure cold mounting machine can accurately control the temperature during the mounting process through the built-in temperature control system. During the resin curing stage, the appropriate temperature helps the cross-linking reaction between the resin molecules, thereby improving the curing quality and strength of the sample. At the same time, temperature control can also effectively prevent the resin from generating internal stress or cracks due to temperature fluctuations during the curing process.

The precise pressure and temperature control of the pressure cold mounting machine makes the prepared samples have the characteristics of no bubbles and no pores. This feature is crucial to improving the flatness of the sample and the accuracy of the test results.

Bubble-free and pore-free samples can reduce errors in the test process. The presence of bubbles and pores may cause instability or distortion of the test signal, thereby affecting the accuracy of the test results. The samples prepared by the pressure cold mounting machine can ensure the stable transmission and accurate measurement of the test signal due to the absence of bubbles and pores inside, thereby improving the reliability of the test results.

Bubble-free and pore-free samples also provide a more reliable basis for subsequent microstructure analysis. Under high-precision analytical instruments such as scanning electron microscopes (SEM) and transmission electron microscopes (TEM), the microstructural characteristics of the sample can be clearly presented. The presence of bubbles and pores may interfere with the accuracy of the analysis results. Therefore, the bubble-free and pore-free samples prepared by the pressure cold mounting machine can ensure the accuracy and reliability of the microstructural analysis.

In addition, bubble-free and pore-free samples can also optimize the performance test results. In experiments such as mechanical properties testing and thermal properties testing, the internal defects and surface unevenness of the sample may lead to deviations in the test results. The samples prepared by the pressure cold mounting machine can ensure the accuracy and consistency of the test results due to the internal defect-free and smooth surface.

The pressure cold mounting machine has shown broad application prospects in many fields with its exquisite craftsmanship and precise control. In the field of materials science, it can be used to prepare samples of metals, ceramics, polymers and other materials; in the field of electronic packaging, it can be used to prepare components in integrated circuit packaging; in the field of geological exploration, it can be used to prepare thin slice samples of rocks and minerals; in the field of biomedicine, it can also be used to prepare slice samples of biological tissues and cells. These applications fully demonstrate the powerful functions and wide application value of the pressure cold mounting machine in specimen preparation.

中文简体

中文简体 英语

英语 西班牙语

西班牙语 德语

德语

.jpg?imageView2/2/w/400/format/jpg/q/75)