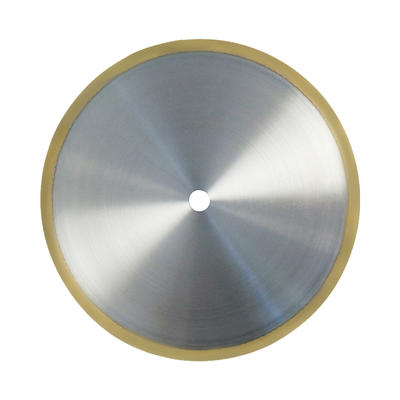

In the field of modern precision machining and material cutting, DR diamond resin bond slicing blades have become an indispensable key tool in many industries with their excellent cutting performance, high hardness and wear resistance. Among them, the complete curing of the resin bond, as the core link in the manufacturing process of this product, has a decisive influence on the overall performance of the cutting blade.

In the manufacturing process of DR diamond resin bond slicing blades, the curing of the resin bond is a crucial step. As a "bridge" connecting diamond abrasive particles, the degree of curing of the resin directly affects the hardness, wear resistance, cutting efficiency and service life of the cutting blade. Incompletely cured resin bonds will lead to insufficient bonding between diamond powder and the matrix, which will easily cause diamond shedding and reduced cutting efficiency during the cutting process. Therefore, ensuring the complete curing of the resin bond is the key to improving the overall performance of the cutting blade.

The curing of the resin bond is a complex chemical reaction process, which usually involves multiple mechanisms such as cross-linking reaction and polycondensation reaction. Under high temperature conditions, the functional groups in the resin molecules react to form a three-dimensional network structure, which tightly wraps and fixes the diamond powder in it. This process not only enhances the interfacial bonding between diamond powder and resin, but also makes the structure of the entire cutting disc more compact and stable.

With the complete curing of the resin binder, the bonding strength between diamond powder and resin is significantly improved. This close bonding enables the diamond abrasive to better exert its high hardness and sharpness during the cutting process and effectively crush the processed material. At the same time, even under high load and high wear conditions, the diamond powder is not easy to fall off from the resin matrix, thus ensuring the long-term stability and durability of the cutting disc.

During the curing process, the fluidity and plasticity of the resin binder gradually decrease, and finally form a stable solid structure. This process helps to eliminate the tiny defects and pores inside the cutting disc and improve the density and uniformity of the material. At the same time, the cured resin binder can also effectively transmit and disperse the thermal stress and mechanical stress generated during the cutting process, protect the diamond abrasive from damage, and further extend the service life of the cutting disc.

The complete curing of the resin binder significantly improves the hardness of the diamond resin binder slicing blade. This increase in hardness comes not only from the high hardness of the diamond abrasive itself, but also from the overall effect formed by the close combination of diamond powder and resin. At the same time, due to the higher wear resistance of the cured resin bond, the cutting blade can still maintain stable cutting performance during long-term use, reducing the performance degradation caused by wear.

The high hardness and wear resistance of the diamond resin bond slicing blade bring it excellent cutting efficiency. During the cutting process, the diamond abrasive can quickly and effectively crush the processed material, reducing the generation of cutting force and cutting heat. At the same time, the cured resin bond can also provide stable support and guidance for the diamond abrasive to ensure the smooth progress of the cutting process. These factors work together to make the DR diamond resin bond slicing blade perform well in cutting efficiency.

The complete curing of the resin bond not only improves the hardness and wear resistance of the cutting blade, but also significantly extends its service life. During the cutting process, even in the face of high-hardness and high-wear-resistant processed materials, the cutting blade can maintain stable cutting performance and reduce the frequency of replacement due to diamond shedding or excessive wear. This not only reduces production costs and downtime, but also improves production efficiency and product quality.

The reason why DR diamond resin bond slicing blades can occupy an important position in the field of precision machining and material cutting is due to the excellent performance brought by the complete curing of its resin bond. During the curing process, a close bond is formed between the resin bond and the diamond powder, which not only improves the hardness and wear resistance of the cutting blade, but also significantly improves its cutting efficiency and service life. With the continuous advancement of technology and continuous optimization of processes, we have reason to believe that DR diamond resin bond slicing blades will show broader application prospects and market potential in the future.

中文简体

中文简体 English

English Español

Español Deutsche

Deutsche

.png?imageView2/2/w/400/format/jpg/q/75)

.jpg?imageView2/2/w/400/format/jpg/q/75)