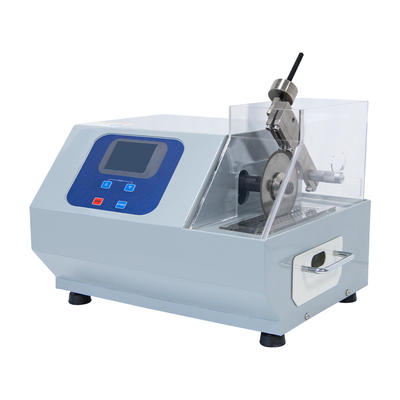

In the field of metallographic analysis and materials science, the quality of sample preparation is directly related to the accuracy of subsequent observation and analysis. Among them, the constant temperature curing process of the metallographic preparation and mounting machine, as a key equipment for sample preparation, plays a vital role in ensuring the quality of samples.

In the metallographic preparation process, mounting is to embed the sample into supporting materials such as resin for subsequent cutting, polishing and observation. The curing of the resin is the key link in this step. The constant temperature curing process not only affects the final physical properties of the resin, such as hardness, toughness, heat resistance, etc., but also directly affects the preparation quality and observation effect of the sample. Curing conditions, especially the control of temperature and time, are crucial to avoid stress, cracks or deformation inside the resin.

The curing of resin is a complex chemical reaction process, in which temperature is a key factor affecting the reaction rate and the structure of the final product. If the curing temperature is too high, it may cause a rapid and violent cross-linking reaction inside the resin, generating a lot of heat and stress, thereby causing cracks or deformation. On the contrary, if the curing temperature is too low, the reaction rate may be slowed down, the curing is incomplete, and the resin hardness is insufficient and the toughness decreases. In addition, the length of curing time will also affect the physical properties of the resin. Too short a curing time may cause the resin to fail to fully cure, while too long a time may cause the resin to age and reduce its performance.

The curing state of the resin directly affects the quality of sample preparation. Incompletely cured resins may deform due to force during subsequent cutting and grinding, resulting in inaccurate sample size and uneven surface. At the same time, the stress inside the resin may cause the sample to shift slightly during observation, affecting the accuracy of the observation results. Fully cured resins can provide stable support for the sample to ensure the smooth progress of the preparation process.

The curing state of the resin also directly affects the observation effect of the sample. Incompletely cured resins may appear blurred or irregular under a microscope, interfering with the observation of the microstructure of the sample. In addition, stress or cracks inside the resin may cause light scattering, reducing the clarity and contrast of the observed image. Fully cured resins can ensure the clarity and accuracy of the observed image, providing a reliable basis for subsequent analysis and research.

In order to ensure the preparation quality and observation effect of the sample, the design of the metallographic preparation and mounting machine fully considers the needs of constant temperature curing, and adopts advanced temperature control system and precise curing parameter control.

Metallographic preparation and mounting machines are usually equipped with high-performance temperature control systems, which can monitor and accurately control the temperature in the constant temperature box in real time. These systems usually use advanced sensors and algorithms to respond quickly to temperature fluctuations and ensure the stability and uniformity of temperature during the curing process. At the same time, the system also has temperature preset and automatic adjustment functions, which can set the appropriate temperature range according to the type of resin and curing requirements to achieve precise temperature control.

In addition to temperature, curing time is also an important factor affecting the curing state of the resin. Metallographic preparation and mounting machines usually provide precise curing time setting functions, allowing operators to set appropriate curing time according to the characteristics of the resin and curing conditions. These settings are usually made through control panels or computer programs, with high flexibility and accuracy. In addition, some advanced metallographic preparation and mounting machines also have the function of recording and analyzing curing curves, which can monitor temperature changes during curing in real time and provide data support for optimizing curing parameters.

In order to ensure the smooth progress of the constant temperature curing process, metallographic preparation and mounting machines are usually equipped with monitoring and feedback systems. These systems can monitor the temperature, humidity and other parameters in the constant temperature box in real time, and alarm or automatically adjust according to the preset threshold. At the same time, the system can also record key parameters in the curing process, such as temperature curve, curing time, etc., to provide important basis for subsequent quality control and data analysis.

In metallographic preparation and mounting machines, precise control of curing parameters is crucial to ensure the quality of sample preparation and observation effect. The following points further emphasize this importance:

By precisely controlling the curing temperature and time, it is possible to ensure uniform and sufficient cross-linking reaction inside the resin, avoiding stress concentration and cracking. This helps to maintain the integrity and stability of the sample and improve the accuracy of the observation results.

Fully cured resin can provide stable support for the sample, ensuring that it does not deform or move during cutting, grinding and observation. This helps to keep the microstructure of the sample clear and discernible, providing a reliable basis for subsequent analysis and research.

Precise control of curing parameters can shorten the curing time and improve the efficiency of sample preparation. At the same time, stable curing conditions help to ensure consistency between different batches of samples, facilitating batch preparation and analysis.

The constant temperature curing process in the metallographic preparation mounting machine usually adopts an automated and intelligent control method, which reduces the difficulty of operation and human errors. This allows operators to focus more on other aspects of sample preparation and improve overall work efficiency and quality.

The constant temperature curing process plays a vital role in the metallographic preparation mounting machine. By precisely controlling the curing parameters, the physical properties of the resin, the preparation quality of the sample and the observation effect can be ensured to be optimal. Therefore, in the metallographic preparation process, the application and optimization of the constant temperature curing process should be highly valued to ensure the accuracy and reliability of sample preparation. With the continuous advancement and innovation of technology, the constant temperature curing process in the metallographic preparation mounting machine will also continue to improve and develop, providing more efficient, accurate and reliable sample preparation solutions for the fields of materials science and metallographic analysis.

中文简体

中文简体 英语

英语 西班牙语

西班牙语 德语

德语