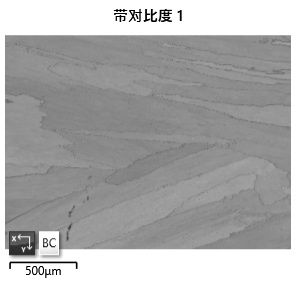

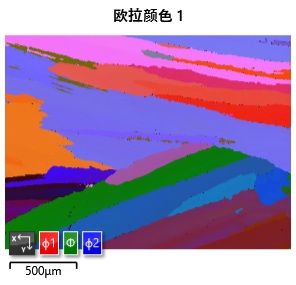

In the field of material research and analysis, EBSD (electron backscatter diffraction) technology has become more and more widely used due to its powerful function of measuring crystal orientation. A flat, clean, and deformed sample surface is a prerequisite for obtaining high-quality diffraction patterns. Mechanical metallographic sample preparation methods are easy to operate and safe, and are more popular than ion thinning instruments and electrolytic polishing. Trojan VP-430 Vibration Polisher Vibration polisher, as a powerful tool for sample preparation, can greatly improve the quality of EBSD Kikuchi patterns and significantly improve work efficiency. The equipment is particularly suitable for surface polishing of soft and tough materials such as titanium, aluminum, pure copper and copper alloys, aluminum alloys, steel and nickel-based alloys. It can be called an artifact for EBSD sample preparation.

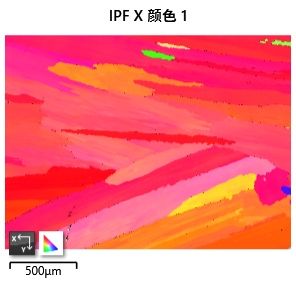

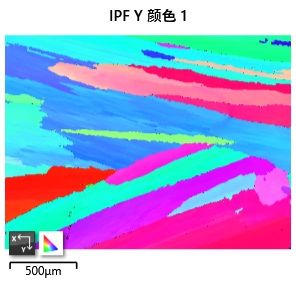

The picture below shows the test results of nickel-based alloy samples prepared by VP-430 vibration polisher, with a calibration rate of up to 99.83%.

中文简体

中文简体 英语

英语 西班牙语

西班牙语 德语

德语

.png?imageView2/2/w/400/format/jpg/q/75)