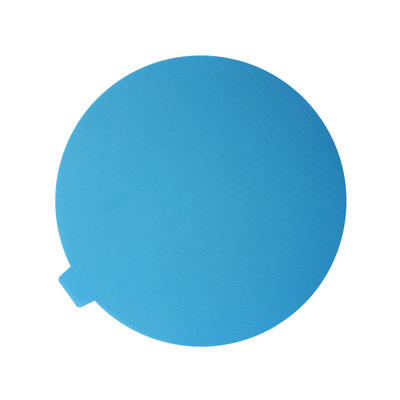

In the field of wood processing, metal cutting grinding discs have become the preferred tool for quickly and accurately completing wood cutting and trimming tasks with their sharp edges and powerful cutting force. As a natural material, wood has extremely high requirements for cutting tools due to its hardness, density and texture diversity. Metal cutting grinding discs use high-hardness alloy steel or silicon carbide and other materials, combined with precise edge design, to ensure stability and efficiency during the cutting process.

Sharp edges can easily penetrate wood fibers, reduce cutting resistance and increase cutting speed. This not only helps to shorten the processing cycle and improve production efficiency, but also effectively reduces wood breakage and waste, and improves material utilization. Metal cutting grinding discs can maintain the sharpness of the edge during the cutting process and reduce the reduction in cutting quality caused by edge wear. This ensures the flatness and finish of the cut surface, providing a good foundation for subsequent processing and surface treatment.

Metal cutting grinding discs are also suitable for wood cutting tasks of various shapes and sizes. Whether it is straight cutting, curve cutting or trimming of complex shapes, metal cutting grinding discs can meet different processing needs with their flexibility and adaptability. This enables wood processing companies to produce wood products of various specifications more efficiently to meet the diverse needs of the market.

In terms of metal cutting, metal cutting grinding discs also show excellent performance. As a hard material, the cutting process of metal is often accompanied by high temperature, high pressure and severe friction. After long-term use, traditional cutting tools are prone to problems such as edge wear and material thermal deformation due to friction heat, which affects the cutting quality and processing efficiency. The metal cutting grinding disc effectively reduces the friction heat during the cutting process, reduces the thermal deformation of the material and the wear of the tool, and ensures the smoothness and precision of the cutting surface through the optimized edge structure.

The edge design of the metal cutting grinding disc adopts advanced geometric shapes and material combinations to ensure stable cutting performance under high-speed rotation. The sharpness and angle of the edge are precisely calculated to form a tiny cutting edge during the cutting process, reduce cutting force and reduce friction heat. At the same time, the metal cutting grinding disc also uses a highly wear-resistant alloy material to improve the durability and impact resistance of the edge. This enables the metal cutting grinding disc to maintain stable cutting performance and good processing quality during long-term, high-intensity cutting operations.

Metal cutting grinding discs are also suitable for cutting a variety of metal materials, including stainless steel, aluminum alloy, copper, etc. These metal materials differ in hardness, toughness, thermal conductivity, etc., and have different requirements for cutting tools. Metal cutting grinding discs adjust the material, shape and angle of the cutting edge to meet the cutting needs of different metal materials. This makes metal cutting grinding discs widely applicable in the field of metal processing and can meet the needs of various complex processing tasks.

The wide application of metal cutting grinding discs in the field of wood and metal processing is not only due to their excellent performance, but also to their wide applicability. Whether it is cutting and trimming wood or cutting and processing metal materials, metal cutting grinding discs can provide efficient and precise solutions.

In the field of wood processing, metal cutting grinding discs can quickly and accurately complete wood cutting tasks of various shapes and sizes with their sharp cutting edges and strong cutting force. This enables wood processing companies to produce wood products of various specifications more efficiently, improve production efficiency and material utilization. Metal cutting grinding discs can also form a smooth and clean cutting surface on the wood surface, providing a good foundation for subsequent processing and surface treatment.

In the field of metal processing, metal cutting grinding discs ensure the smoothness and precision of the cutting surface with their optimized blade structure and wear-resistant alloy material. This makes metal cutting grinding discs perform well in processing tasks such as cutting, drilling, and grooving of metal materials. Metal cutting grinding discs are also suitable for cutting a variety of metal materials, including stainless steel, aluminum alloy, copper, etc., meeting the diverse needs of the metal processing field.

中文简体

中文简体 英语

英语 西班牙语

西班牙语 德语

德语

.jpg?imageView2/2/w/400/format/jpg/q/75)

.jpg?imageView2/2/w/400/format/jpg/q/75)