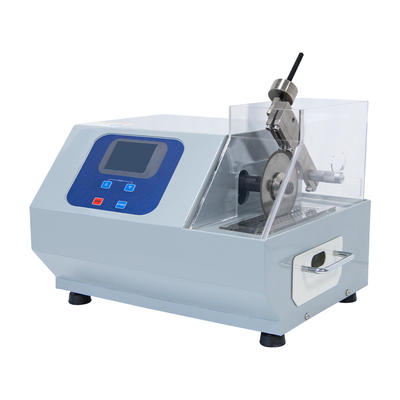

UVmount is a sample preparation device that uses UV light source to irradiate light-curing resin to quickly achieve high-quality transparent sample cold mounting. The device has the following core advantages:

- Extremely fast curing, efficiency leap: It only takes 60 seconds to complete resin curing, which shortens the sample preparation time by more than 90% compared with traditional cold mounting technology, and supports batch rapid mounting processing;

- Adjustable illumination time parameters: Supports free setting of irradiation time, and is equipped with 4-speed timing quick settings to adapt to different types of resins and sample requirements;

- Bubble-free transparent samples, high quality guarantee: Through the upper and lower double-layer UV light source uniform irradiation technology, complete curing from the inside out is achieved to eliminate bubbles;

- High transparency of resin: After curing, the sample transparency is extremely high, meeting the clear observation requirements of metallographic analysis, electronic component detection and other scenes;

- Simple operation: One-button start of fully automatic process: electric door opening and closing, automatic sample feeding/discharging;

- 4.3-inch touch screen: real-time monitoring of parameters, 4 preset quick curing modes for quick switching;

- Dual fan cooling system: the peak curing temperature is lower than 90°C to avoid thermal damage to the sample;

- Environmental protection and safety upgrade: optional exhaust purification module: adsorbs volatile gases generated during the curing process to prevent odor diffusion (optional);

Application scenarios:

- Metallographic laboratory: rapid sample preparation and microstructure analysis of metals, alloys and other materials;

- Electronics industry: non-destructive packaging and defect detection of chips and PCB boards;

- Geology and materials research: transparent bonding and curing of complex samples such as rocks and composite materials.

中文简体

中文简体 英语

英语 西班牙语

西班牙语 德语

德语

.png?imageView2/2/w/400/format/jpg/q/75)