Polishing is to improve the surface finish of the polished object, improve accuracy and performance, and enhance surface protection and remove impurities on the surface of the object. Therefore, the effect of the polishing liquid directly affects the effect of the above-mentioned aspects. Therefore, in order to ensure product quality, Trojan has conducted strict internal testing on each batch of polishing liquid. The main feature of alumina polishing liquid is good chemical stability and is not easy to corrode the sample surface. Although it is second only to the hardness of diamond, it also brings high polishing efficiency and wide applicability such as stainless steel, aluminum alloy, copper alloy, etc., as well as non-metallic materials such as glass, ceramics, semiconductor materials, etc.

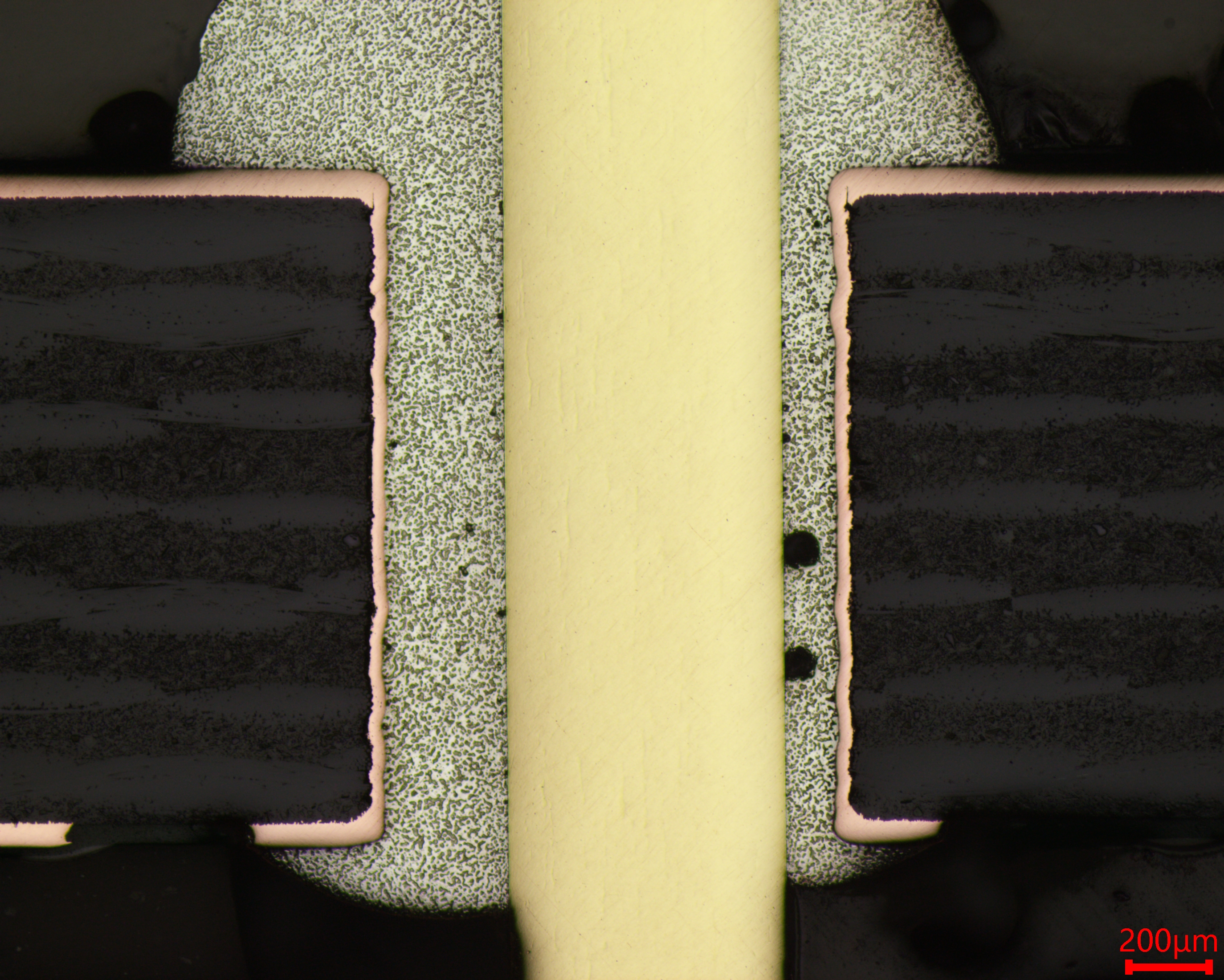

The following is the metallographic picture effect appreciation of the alumina polishing liquid developed by Trojan after polishing at different times during the test process.

中文简体

中文简体 英语

英语 西班牙语

西班牙语 德语

德语