First of all, we have to choose a polishing cloth. What kind of polishing cloth is generally used for metallographic polishing of austenitic stainless steel? Is the gold velvet polishing cloth austenitic stainless steel? Gold velvet polishing cloth is good, but it is suitable for polishing stainless steel. But in the actual test, no one deliberately chooses what polishing cloth, as long as the polishing cloth without scratches can be thrown.

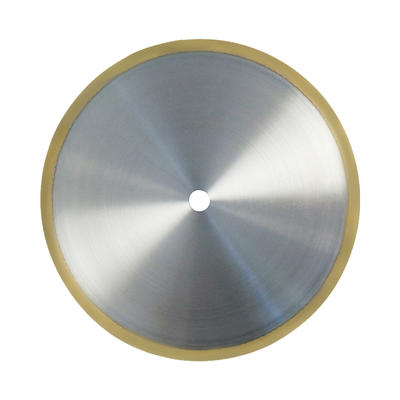

How to use metallographic polishing machine to polish without scratches? To polish without scratches, the key is to work hard when grinding on the sandpaper in the early stage. Start with small sandpaper and grind to 2000 sandpaper step by step. Before applying the polishing cloth, make sure that there are no rough scratches on the phase sample. scratches, and the scratches are all in one direction. In this way, adding polishing paste (made by alumina polishing powder VK-L30F, 0.3um is the best) on the polishing cloth, it is easy to grind to a qualified sample.

It is very important to grasp the strength when polishing. The strength can be higher when rough throwing, but the strength should be very suitable when fine throwing. Generally, the sample just touches the polishing cloth, in the direction perpendicular to the polishing cloth. Almost effortless. Gold velvet is used for fine polishing, generally 0.3 alumina polishing paste is used. When rough polishing, you can use material or short pile. I think 2.0 or 1.5 polishing paste is almost the same, if it is well ground in the early stage. In the early stage, the sandpaper is ground in the same direction. When rough polishing, it can be perpendicular to this direction until the large scratches disappear.

中文简体

中文简体 英语

英语 西班牙语

西班牙语 德语

德语

.jpg?imageView2/2/w/400/format/jpg/q/75)

.png?imageView2/2/w/400/format/jpg/q/75)

.png?imageView2/2/w/400/format/jpg/q/75)