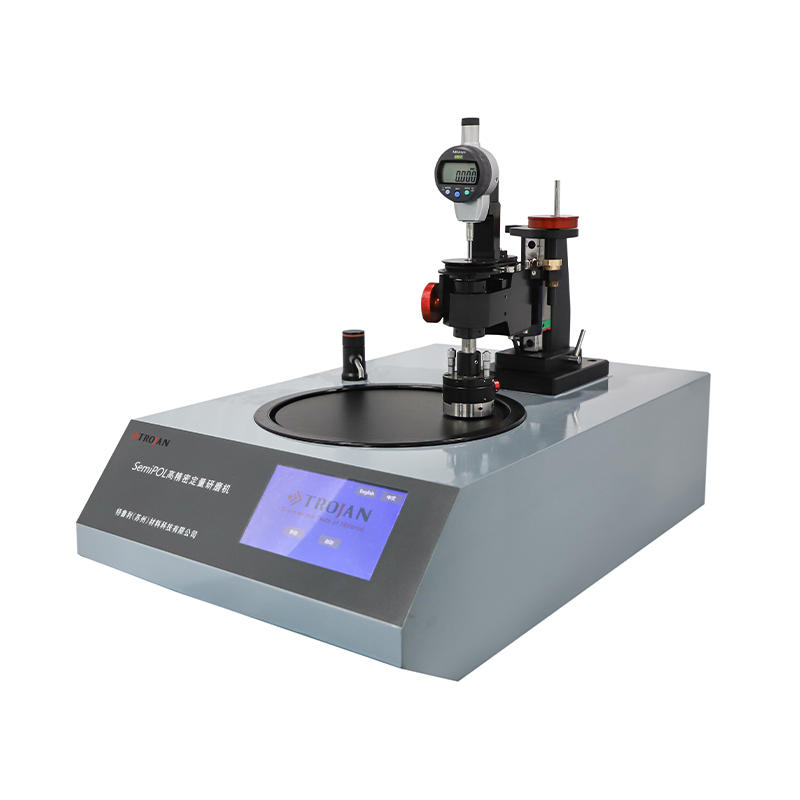

The selection of the grinding wheel has a significant impact on the quality of metallographic samples. Here are some key ways it affects the final result:

Material Removal Rate: Different grinding wheels have varying abrasive properties, hardness, and grit sizes. The choice of the right wheel can influence the material removal rate during grinding. Using a wheel with an appropriate grit size and hardness ensures controlled material removal, preventing excessive removal or damage to the sample.

Surface Finish: The grinding wheel's abrasive properties and surface texture directly affect the final surface finish of the metallographic sample. An improper choice can lead to surface roughness, scratches, or unwanted artifacts that may interfere with accurate microstructural analysis.

Edge Retention: When grinding small or delicate samples, the grinding wheel selection becomes crucial to maintaining the integrity of the sample's edges. A properly chosen wheel with the right hardness and shape helps retain the sample's original features and prevents edge chipping.

Heat Generation: Some grinding wheels may generate more heat during the grinding process due to their composition and hardness. Excessive heat can alter the microstructure of the sample, leading to inaccurate results. Selecting a wheel with lower heat generation properties is essential for preserving the sample's true structure.

Wheel Wear: The wear rate of the grinding wheel is another factor to consider. A wheel that wears too quickly can result in uneven grinding and variations in the sample thickness, affecting the overall quality and consistency of the metallographic sample.

Contamination: Using an inappropriate grinding wheel can introduce foreign particles or contaminants into the sample, leading to cross-contamination and compromising the accuracy of subsequent analyses, such as microscopy or elemental analysis.

To ensure high-quality metallographic samples, it is essential to choose a grinding wheel that matches the specific characteristics of the material being analyzed and the desired end result. The selection should consider factors such as abrasive type, grit size, hardness, bond type, and porosity. Additionally, regular inspection and maintenance of the grinding wheel are crucial to maintaining consistent performance and ensuring accurate and reliable results in metallographic analysis.