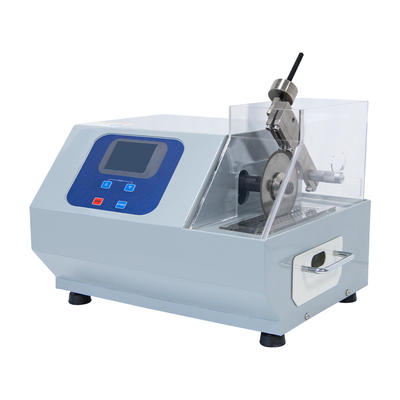

In the rapid development of the manufacturing and packaging industries, the automatic laminating machine has become an indispensable and important equipment with its high precision and high efficiency. In particular, the perfect combination of its high-precision sensors and servo motors not only ensures the accuracy of positioning, but also achieves the perfect fit of labels or paper with the product surface during the laminating process.

The core of the automatic laminating machine lies in its precise positioning system. High-precision sensors are the key to this system. They can capture the position information of labels or paper in real time and transmit these fine data to the control system. Servo motors, as actuators, perform high-speed and precise position adjustments according to the instructions of the control system. The collaborative work of this sensor and servo motor enables the automatic laminating machine to maintain extremely high positioning accuracy in a complex and changeable industrial environment, laying a solid foundation for subsequent perfect laminating.

During the laminating process, factors such as the material, shape and size of the product surface often vary greatly. This requires the automatic laminating machine to have a high degree of adaptability and flexibility. Through the built-in intelligent algorithm, the automatic laminating machine can identify the surface characteristics of different products and automatically adjust parameters such as laminating force, speed and angle. This intelligent adjustment not only ensures that the label or paper can fit tightly on the product surface, but also avoids the occurrence of problems such as bubbles, warping or misalignment.

Perfect fitting is not only the basic function of the automatic laminating machine, but also the key to increasing the added value of the product. Through the cooperation of high-precision sensors and servo motors, the automatic laminating machine can complete complex laminating tasks in milliseconds, so that the label or paper can be seamlessly connected to the product surface. This perfect fit not only improves the overall aesthetics of the product, but also enhances the brand image and market competitiveness of the product.

With the continuous advancement of technology and the continuous changes in the market, the automatic laminating machine will continue to usher in more development opportunities. In the future, the automatic laminating machine will achieve greater breakthroughs in the following aspects:

Higher precision: By introducing more advanced sensors and control systems, the automatic laminating machine will achieve higher positioning accuracy and laminating quality.

Stronger adaptability: In response to the needs of different industries and different products, the automatic laminating machine will have stronger adaptability and flexibility, and can meet a wider range of laminating needs.

More intelligent: With the help of cutting-edge technologies such as artificial intelligence and the Internet of Things, the automatic laminating machine will achieve more intelligent operation and management, improve production efficiency and reduce labor costs.

In short, the automatic mounting press plays an increasingly important role in the manufacturing and packaging industries with its precise positioning and perfect lamination capabilities. In the future, with the continuous advancement of technology and the continuous expansion of application fields, the automatic laminating machine will continue to bring more surprises and changes to industrial production.

中文简体

中文简体 英语

英语 西班牙语

西班牙语 德语

德语

.png?imageView2/2/w/400/format/jpg/q/75)

.jpg?imageView2/2/w/400/format/jpg/q/75)